Guilloche All Day

If you read the title of this article and thought to yourself “that’s not a real word,” then you’re likely not alone. While you may not have heard of guilloche (pronounced "gee-oh-shay") before, you have almost certainly seen it. Guilloche is a technique used to create intricate patterns on surfaces, in the case of watchmaking, most commonly on the watch dial. While the purpose of guilloche is primarily decorative, it can also serve to improve legibility by creating contrast and reducing glare. Guilloche has historically been a highly labor-intensive process, requiring skilled artisans spending many hours to create a single dial; however, new tools and techniques have made it more accessible in modern times. In this post, we'll explore some of these techniques and their applications.

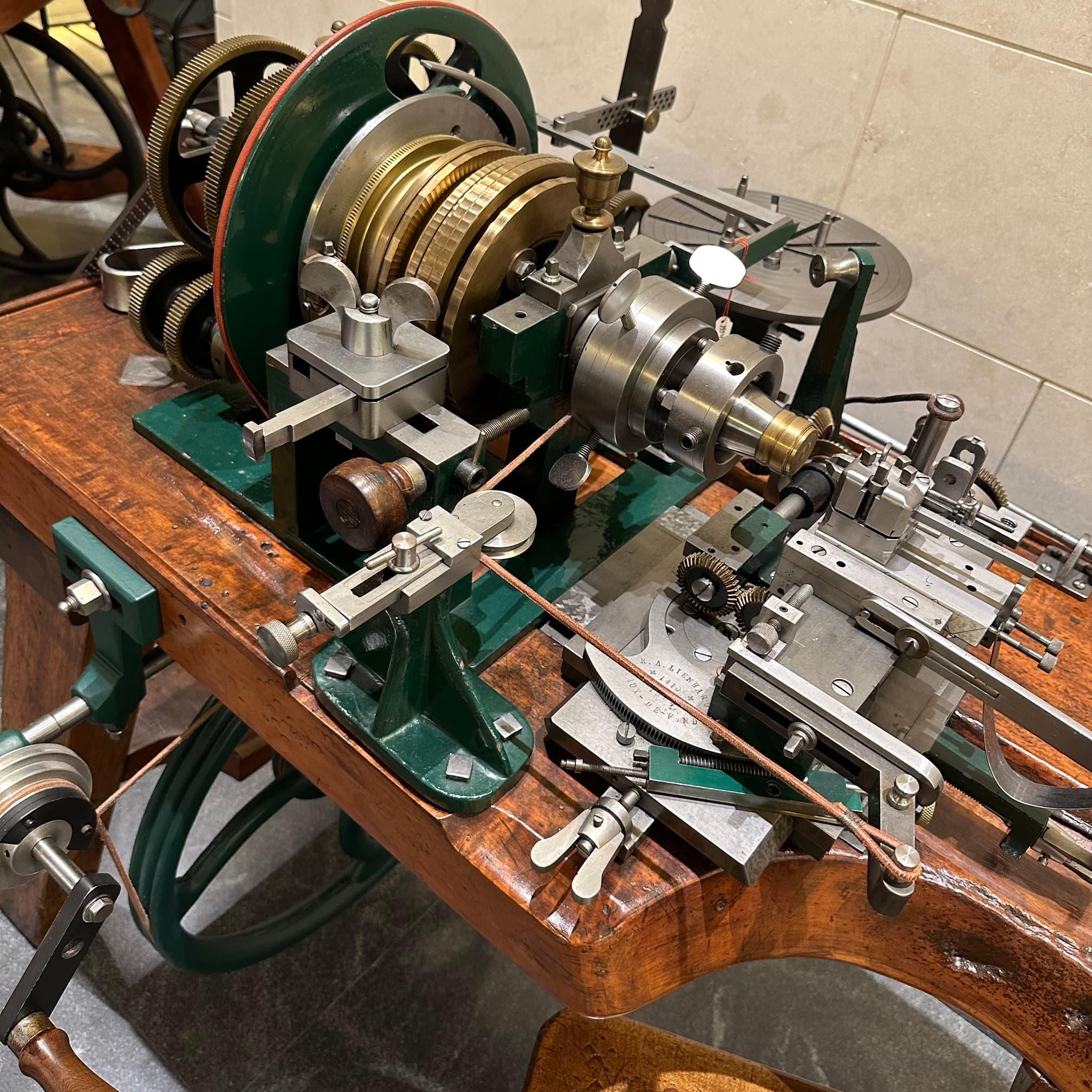

The practice of guilloche goes back to the 1500s, when it was primarily used to create patterns on wood and ivory using engine turning machines. In the 18th century, the invention of the rose engine lathe allowed the technique to be applied to metal and in much finer detail[1]. The use of traditional hand operated rose engines involves affixing a metal plate to the lathe, then using rosettes (specially shaped rotating wheels) to move the lathe to cut a pattern into the metal. Position, speed, and pressure are all manually controlled, with some dials involving more than 1000 distinct cuts to complete.

Guilloche dials most often start from a solid dial plate made of a soft metal, such as gold or brass. After cutting, dials are generally finished with a combination of silvering, lacquer, and/or enamel. These finishing techniques result in a translucent layer over the patterning, which further adds to the depth of the dial.

Hand Turning and Rose Engines

Last summer, I was fortunate enough to visit the Jaeger-LeCoultre manufactury (where I also learned the correct Swiss-French pronunciation is “Jeyjey-le-cootreh”). While the tour was amazing, and I would highly recommend it to anyone who finds themselves in the Vallee de Joux, one of the things that most stood out to me was the difference in techniques used between their “High Watchmaking” pieces and a run of the mill Reverso or MUT.

JLC makes their high horology pieces in a different space from their general production watches, where slipper footed artisans separated from the dust and dander of the outside world by floor to ceiling glass walls produce minute enamel case paintings and tinker with unimaginably complex mechanisms. In one such glass viewing cube, one of JLC’s two engravers trained to use the antique rose engines methodically carves line after line into a solid gold dial plate barely visible from a few feet away. Other than a strategically placed work lamp, nothing else in the space requires electricity; mechanical pulleys, cranks and couter-weights drive the reduction gears, which allow the artisan’s movements to be translated into minute details.

There is believed to be less than 100 people in the world capable of operating such machines, with the majority of them within the Vallee de Joux. Some brands, such as Breguet, use these manual rose engines exclusively for their guilloche work. Others, like JLC, use a mix of traditional hand turning, mechanically assisted lathes, or other techniques, which we’ll discuss in the next section.

Modern Guilloche Tools

The main assembly floor of the JLC manufactory was a stark contrast to the artisan filled glass cages of the high horology area. Skilled workers in white lab coats sat at meticulously maintained workstations, each equipped with its own specialized machine. I’ll cover the whole experience in a future post, but one of the most apparent themes of the space was the juxtaposition of complex, automated tools and equally complex antique tools.

Toward the middle of the assembly floor, a half dozen workers were using electric lathes to hand cut the guilloche patterns into Reverso dials. While these machines eliminated the need for the workers to manage counter-weights and swapped cranks for levers, the process was still very much done by hand. The time and skill intensive nature of hand work, even when mechanically assisted, means that such dials are generally reserved for higher end pieces and manufacturers; however, modern watchmaking has found ways of achieving similar results in much more cost effective and scalable ways.

Another technique that has become more popular in recent years is the use of CNC machines. These machines use computer-controlled cutting tools to create the guilloche pattern, and can produce very precise patterns in a fraction of the time it would take a human to do by hand. While these machines are not capable of the same level of detail as a hand turned guilloche, they are capable of producing very intricate patterns with a high degree of precision and consistency.

Other Patterning techniques

While guilloche is the most traditional patterning technique, there are a number of other approaches that watchmakers have taken to produce similar results, often in far more cost effective and scalable ways. The most common of these methods is metal-stamping, which uses a metal stamp to press a pattern in a softer metal, such as brass. The dial can then be coated with a lacquer or enamel to achieve a similar effect to guilloche. Dials made in this way are quick to produce and much more cost effective at scale, but are not capable of the same level of detail and depth as guilloche.

Other techniques, such as etching (either by machine or using chemicals), laser cutting, and even 3D printing are also used to create similar patterning effects, but are not as common.

Conclusion

While guilloche is a highly skilled and labor intensive process, it is still the gold standard for creating intricate and detailed patterns on watch dials. While the cost of producing a guilloche dial is still higher than other methods, the level of detail and quality that can be achieved is unmatched. As the technology continues to evolve, we may see more and more watches with guilloche dials, but the traditional hand turned guilloche will always be a highly valued and sought after technique.

References

Comments

Sign in to leave a comment